DISPLAY BASE FOR CHAOS ARMY

Since my brother went to Krems this year (editor's note: 2005) for the second time for the Austrian Championship, and the display base is one of the conditions for the community there to participate in the tournament, here's how I put in the effort and made one.

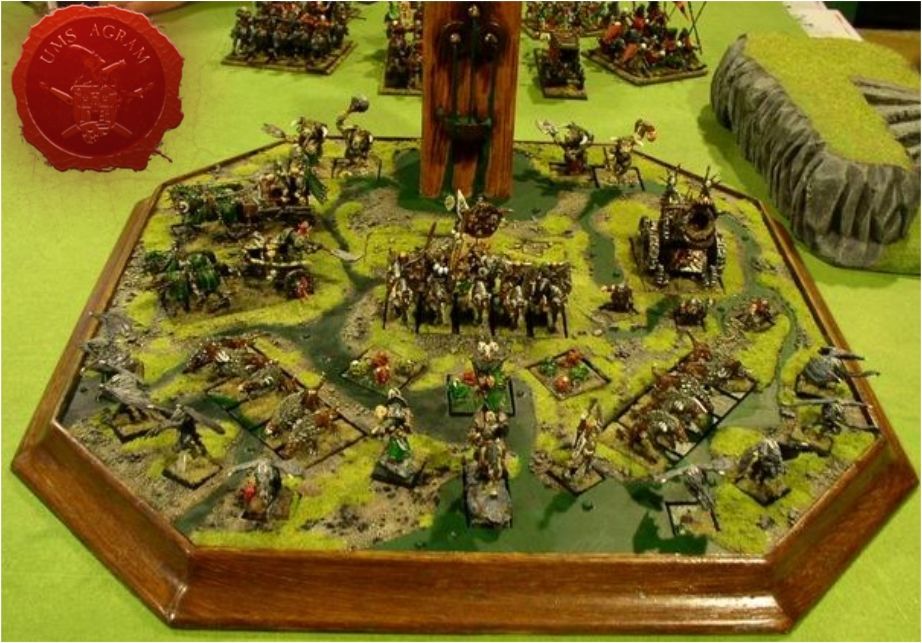

To clarify one thing, display bases (hereinafter DB) that are made in such a way that a certain surface is flocked, painted, maybe some extra features, and the figures are placed on it is for me a halfassed solution - in short, a lot of work for something that looks average. I consider a DB to be da bomb when each unit or individual figure has its own slot in which it is placed so that the surface of the base of the figure is flush with the surface of the DB.

Dissatisfied with the fact that the DB created in this way is useful while the list for which it was made is current, I decided to make a display base that will be applicable to each list (at least its main part), and only the surface will change - when you go deeper into the text , you will understand what I meant.

1. Found a suitable board (2 cm thick)

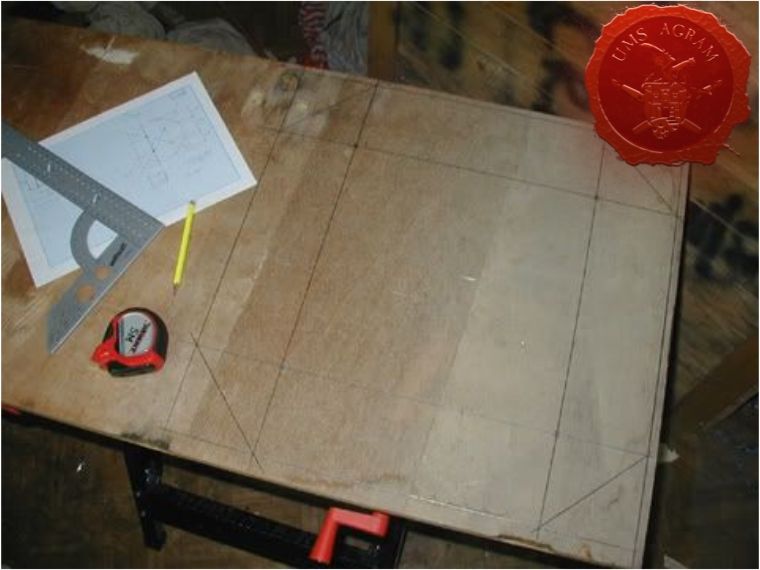

2. Since my rectangular shape is too ordinary, I decided to complicate things a bit and make a non-real octagon (by that I mean 4 sides of the same length). I made a draft and transferred it to the board:

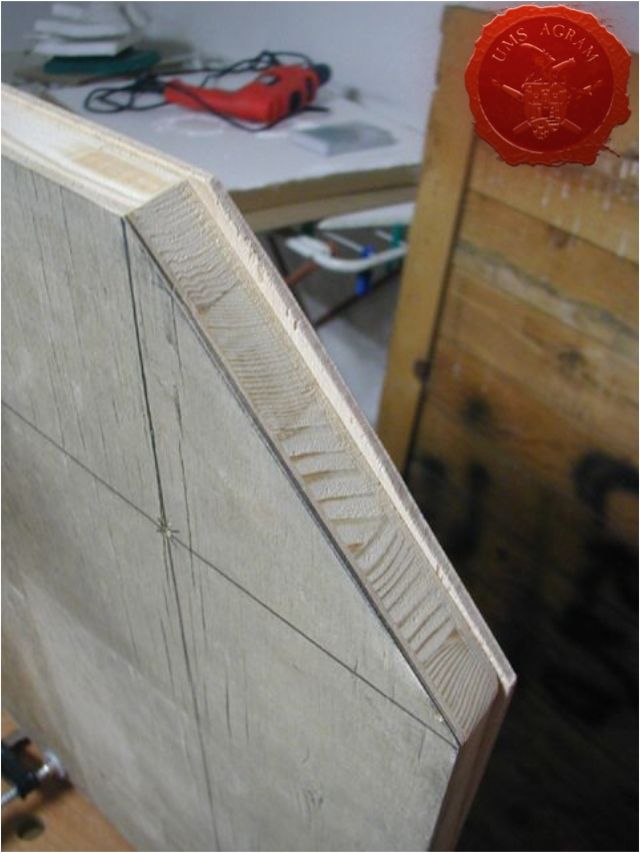

3. I got rid of the excess with a jigsaw, so now the DB has a shape in which the angles are under 150 degrees, 4 sides 30 cm long, and the other four 14 cm + a couple of millimeters, which will later be removed by planing and grinding.

Tip: Never cut the board to the desired dimension but leave 2-4 mm due to the above procedures later:

4. I also cut a 4 mm thick plywood board to the same shape (the figure bases are 4 mm thick):

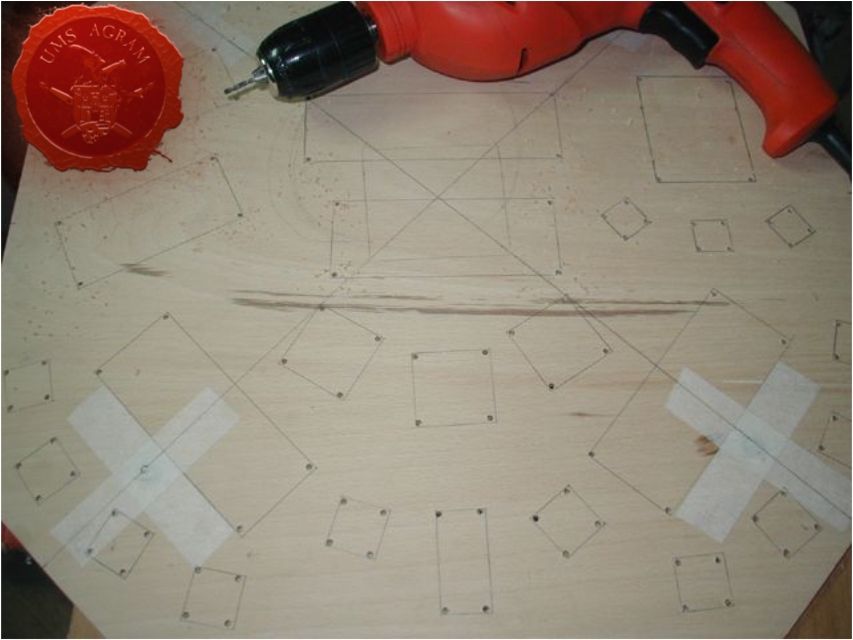

5. I made 4 holes in the board and plywood with a drill, which will later be fitted with screws that will fix the plywood to the main board:

6. Then I widened the holes on the plywood so that the nut would fit in them. I used screws fi = 5 mm and the nut for them is 4 mm thick so it won’t protrude beyond the plywood. After that, the joint between the nut and the plywood is well sanded with super glue, making sure that the glue does not go on the thread because it could later interfere with the screw:

Tip: Since the nut in the board must be fixed, it is desirable to drill a 1 mm smaller hole, and then drive it into the board with a hammer and brutal force.

7. After the nut is fixed, for the first time the plywood and the main plate are connected with screws in order to determine how long the screw needs to be and to remove the excess:

It looks like this:

8. After the screw was shortened to the appropriate length, I covered the nuts on the top of the plywood board with masking tape so that I could texture that surface later.

9. After that I joined the boards and due to the inaccuracy in cutting the boards and drilling the holes the edges looked like this:

10. In order to achieve that the edges match, the excess needs to be planed, and then finely sanded. After this procedure the condition is as follows:

11. After processing the edges with a vibrating grinder, I sanded all the surfaces on the plywood and the main board:

12. The next and most demanding step is to place the decorative moldings on the edges of the board. I took 3x3 cm high / wide corner skirting boards for parquet length of 2 m. The skirting board is coated with wood fix, joined to the board, and then I additionally fastened it with nails:

13. After installing the moldings the whole thing looks like this:

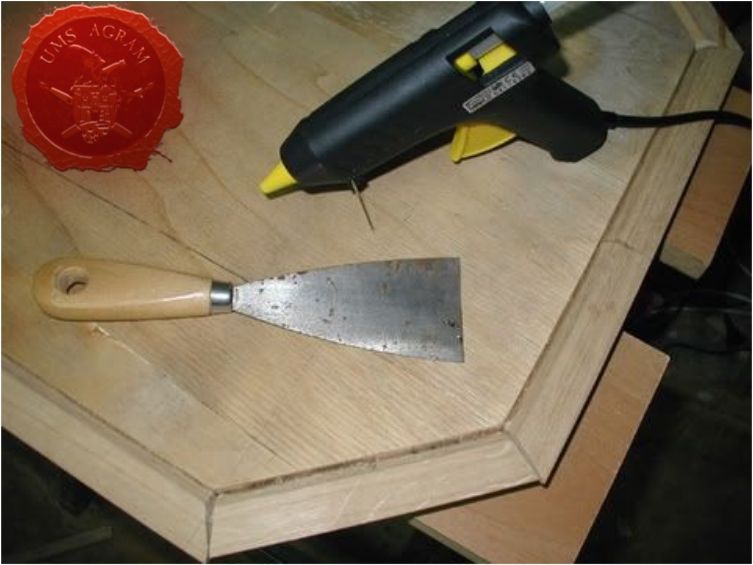

14. As the angle on the legs of the molding is not right, but it is cut obliquely, it happened that I have a "groove" on the lower side between the molding itself and the plate. This proved to be a happy coincidence because knowing your brother (a man is able to tear a steel ball) any extra fixation comes in handy. I filled the grooves with hot glue using a gun (I guess you know which tool I'm talking about):

15. As I approached the plane of the board and molding any excess glue that might protrude over that plane I straightened with a spatula while the glue was hot and liquid. After gluing, the underside of the board looks like this:

16. Since I don't have the right tools (saw stand)), I had to determine the angles of 150 degrees between the moldings by eye only, and especially because I'm not a carpenter, the next thing happened:

17. I sanded the joints to get rid of the protruding parts, and I cracked the cracks between the moldings using carpentry putty and left it to dry overnight. The next day I sanded the putty with fine sandpaper to make a perfect transition between the two strips and the putty and so that after painting everything together I would not see the difference between the putty and the wooden part.:

18. Now it's time to paint. I protected the moldings with protective tape:

19. Then I painted the board between the moldings with black matt spray and left it to dry:

20. After that, it was time to paint the moldings. I protected the previously painted black surface with a protective tape:

21. I used brown wood paint with integrated varnish which, in addition to protecting, also gives a gloss effect. I took a darker shade (rosewood) because the darker color covers the putty better.

Tip: Apply the first coat only on putty parts and wait for the paint to dry well. After that, in the second painting, paint the complete moldings. Two or three coats of well-smeared coat should be enough for a nice coverage - of course, between each coat you should wait for the previous one to dry well:

22. A few more small details and the main board is ready. I bought wood wallpaper for the underside of the DB - black wallpaper with rings - it definitely looks the most convincing and least cheap:

23. After installing the wallpaper, the underside of the DB looks like this:

24. The final job on the DB main panel is varnishing the screws and black so that the metal head of the screw does not look ugly on the black wallpaper:

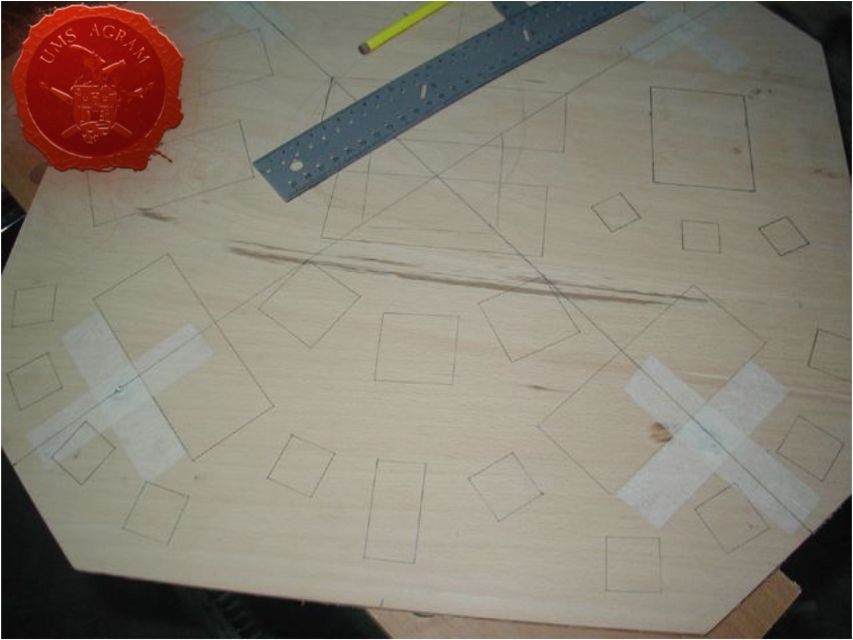

25. Now it's the plywood board's turn. I placed the unite on it and marked the parts to be removed according to them:

26. After that, I drilled holes in the corners for cutting with a jigsaw:

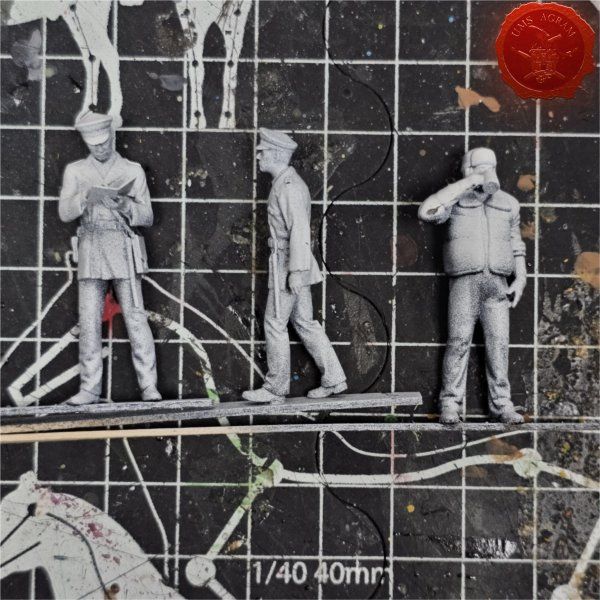

27. After cutting the excess and sanding the plywood looks like this:

Tip: When cutting, it is good to make sure and make a 1 mm bigger hole for the bases, because if you cut too small a hole later, it is a real pain to grind the part that bothers you so that the base fits nicely into the hole.

28. The next step is to text the plywood. I will not talk too much about this because the procedure is the same as when texturing the most ordinary terrain:

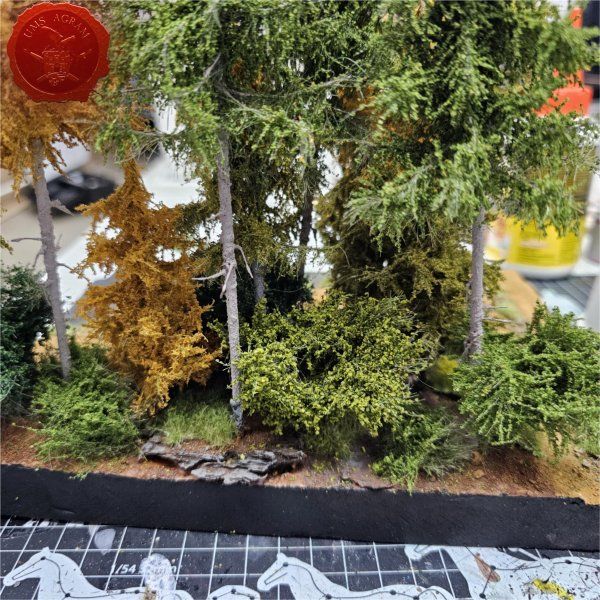

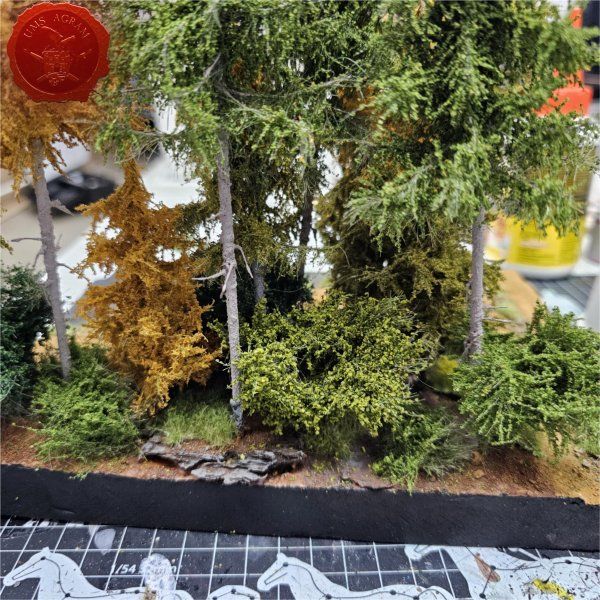

29. Since the Austrians also demand some extra feature on the DB, we decided to make a monolith dedicated to the nurgle god. I cut it out of a piece of wood, processed it by planing and grinding, and then made indentations with a flexor. The flexor may be an unorthodox tool for making models (especially if they are made of wood), but it is very effective. The dead-line that hung dangerously on my back at that stage of making DB makes all sorts of ideas fall through in order to speed up the work:

30. Later we decorated the monolith with, for a nurgle, the characteristic three circles arranged in a triangle using large screw plates, added waterlogging heads from chaos tank sprue, added a tray made of half a plug of Ax dezic, a hot glue gun made slime leaking waterlogged from the mouth into the tray and then overflowing over the edge and dripping down the monolith to the base. Relatively simple special feature, and yet in the spirit of the military. I fixed the monolith with wood fix and plywood nails and when everything was in place I undercoated with black matt spray:

That in short (well, not very short) would be that.

The point is that one day, when the list is changed, this plywood is replaced with another plywood, which will be cut according to a template that matches the new list, with maybe some new feature instead of a monolith to refresh the impression a bit, and the base itself to be further usable.

I hope that the text is clear enough and that there are enough pictures and that those who will one day want to make their DB, but are not sure where to start and how to finish the job will benefit from this text.

P.S.

Still, a few words of warning because not everything is as simple as the text suggests.

FIRST

The circular saw is a dangerous tool, and I definitely have no luck with it. A year ago, he almost tore off my left index finger. This time, fortunately, she was excluded, but even then she showed her insidious nature (a sharp knife that looks benign while static).

SECOND :

I don’t know about you, but the mess I leave behind in creative ecstasy is, to put it mildly, terrifying. I think I’ll avoid the basement for a while because I get depressed every time I see how much cleaning awaits me.

Ok, I’m finally done writing.

Latest articles

- SFRJ 1986 v2 Diorama part 5 Marko Paunović, 19th January 2026

- SFRJ 1986 v2 Diorama part 4 Marko Paunović, 19th January 2026

- SFRJ 1986 v2 Diorama part 3 Marko Paunović, 19th January 2026

- SFRJ 1986 v2 Diorama part 2 Marko Paunović, 19th January 2026

- SFRJ 1986 v2 Diorama part 1 Marko Paunović, 19th January 2026

Latest battle-reports

- Kill Team - Blooded vs. Vespid Stingwings 28th February 2025, GW - Warhammer 40.000, and Antoni Pastuović (Imperial Guard)

- 22nd April 2022, GW - Warhammer 40.000, Borna Pleše (Space Marines) and Kristijan Kliska (Tau Empire)

- 17th November 2021, GW - Warhammer 40.000, and Nino Marasović (Space Marines)